- Homepage

- Corporate

-

Investor Relations

-

Corporate Governance

- General Information

- Corporate Governance Principles Compliance Report

- Corporate Governance Compliance Rating Report

- Board Of Directors of İskenderun Demir ve Çelik A.Ş.

- Management Team of İskenderun Demir ve Çelik A.Ş.

- Ownership Structure

- Trade Registry Information

- Articles of Association

- Information About the Privileged Share

- Safe Harbour Statement

- Code of Ethics and Business Conduct

- Policies and Regulations

- Committees

- Internal Directive on the Operation Principles and Procedures of the General Assembly

- Independent Auditor

- Reports and Presentations

- Annual Reports

- Disclosures and Announcements

- General Assembly

- Dividend Payments and Capital Increases

- Credit Ratings

- FAQ

- Contact US

-

Corporate Governance

- Sustainability

- Career

- OYAK Mining Metallurgy ;

Occupational Health and Safety

Occupational health and safety (OHS) is our first priority

In all our processes we act with the principle that all accidents can be prevented and work with an objective of ensuring accident-free production by minimising all possible risks. In our Group where exemplary behaviours are rewarded and motivation building occupational health and safety practices, such as the provision of world class personal protective equipment, are in place, undertake to work with the motto of “Accident-free Steel” in line with the principles highlighted in our OHS policies.

- Producing accident-free steel by implementing a risk management system,

- Protecting the health of the employees by providing them with a safe working environment,

- Making the employees adopt and claim responsibility for a sustainable safety culture.

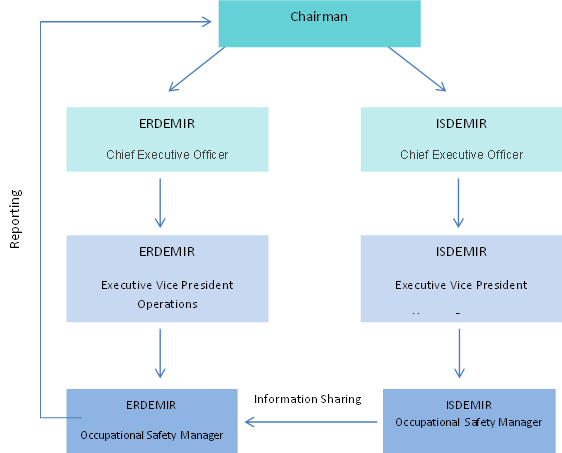

Organisational Structure of our Occupational Health and Safety System

Since 2000, Erdemir has been successfully conducting the work on “Identifying and Eliminating Risks” as required by the Work Health and Safety Law No. 6331 which was put in effect on 30 June 2012 therefore, it is now the leader of the sector in OHS practices.

Within the framework of TS 18001 (OHSAS) Occupational Health and Safety System which is implemented by our companies, our Group conduct various activities including OHS meetings; unit OHS board and sub-committee meetings; informed-uninformed security checks; “yellow card” and “near miss” practices; emergency drills; appointing direct WHS engineers to all units, and; regularly sharing OHS practices on Erdemir Group’s Internal Communications Bulletin “From Steel to the Future”.

In 2006, to make a systematic study of philosophy of doing business, with a view to increasing Occupational Safety performance and making target oriented, Erdemir launched the “unit work health and safety engineers” practice. This practice consisted of sector-based experts, all specialised in their area of operations, and as such it was a first application in Turkey. Under the Occupational Health and Safety Management, including the unit OHS experts, we have a total of 26 OHS experts each of whom has an A Class certificate which is the highest level in OHS expertise and authorises the employees to work in all hazard classes.

To make sure that our employees internalises WHS rules and develops and maintains a culture of safety, we attach great importance to conducting awareness raising activities in this field. In 2013, we delivered a total of 26 hour OHS training per employee, which made their share in the overall training activities 49% for Erdemir only.

| Erdemir Whs Indicators | ||||

|---|---|---|---|---|

| 2013 | 2012 | 2011 | 2010 | |

| Mandatory Ohs Training (Participant/Hour) | 59.931 | 8.266 | 24.954 | 13.809 |

| Additional Ohs Training (Participant/Hour) | 121.342 | 84.707 | 87.878 | 79.616 |

| Total Ohs Training (Participant/Hour) | 181.273 | 92.973 | 112.832 | 93.425 |

| Training Per Person (Hour) | 26,20 | 14,02 | 16,83 | 13,67 |

| Measures Taken To Near Misses (Number) | 246 | 252 | 317 | The records have been entered in the system since 2009 and the results have been followed since 2011 |

| Measures Taken To Hazard Notice (Number) | 1244 | 1205 | 1289 | |

| Other Ohs Improvements (Number) | 2175 | 2837 | 2221 | |

One of the best practices in Europe

We represented Turkey with the Erdemir Risk Assessment System (ERDS) which we developed with our own software group in 2009 at the 9th Europe Best Practices Contest organised by the European Occupational Health and Safety Agency. ERDS was chosen the “recommended application” in Europe and was included in the “Good Practices Booklet” published in EU member and candidate states.

Erdemir Risk Assessment system was also represented for the Turkish Ministry of Labour and Social Security at the A+A WHS Trade Fair, which is one of the biggest OHS Trade Fairs in the world, in Dusseldorf Germany between 5-8 November 2013. Additionally, our system was also presented at the following events organised by the Ministry of Labour and Social Security:

- Risk Assessment and Practices in Metal Sector Seminar held at the Konya Chamber of Commerce on 29 June 2012,

- Europe Occupational Health and Safety Week Risk Assessment Campaign Symposium at the Karabük University on 27 April 2010.

Sharing good practices

We follow the good practices and developments in OHS field and we are a member of the Health and Safety Committee of worldsteel. In 2014, the Union identified five main factors for the fatal accidents occurred in the steel sector (Moving Equipment, Fall From Height, Falling Object, Working in Gaseous Areas, Cranes) and suggested that companywide informed security checks should be done according to the defined criteria. So, in the first 6 months of 2014 we organised fully informed security checks at our Group with the participation of our 26 unit managers as well. We shared 5 of the 120 good practices we identified during those checks with Worldsteel and received a proposal from them to publish these practices in the Worldsteel Excellence Recognition report.

In 2014; we attended, as a trainer with our A class OHS expert, the Efficient and Reliable Use of Resources for OHS (FERROSH Project) in Metal Sector in Turkey. It was a joint project prepared by Turkish Metal Industrialists Trade Union – MESS, The Netherlands Applied Scientific Researches Institute – TNP and Turkey Public Health Institute with a view to increasing the OHS awareness of MESS member organisations. Under the project, we delivered training to the MESS members in the Bursa area between 26-30 May 2014 and shared Erdemir’s work health and safety practices with them.

In addition to their OHS activities, our Group companies extend their support to the public authorities in cases of emergency at their hometowns both with their trained personnel and available equipment. Our Firebrigade Unit is not only an expert team in responding to industrial fires but also is structured so that they are ready for deployment to respond to emergencies any time of the day without requiring a further instruction.

After the Gölcük and Düzce earthquakes in 1999, we set up ERDAK (Erdemir Research and Rescue Team) with the voluntary participation of 22 Erdemir personnel to respond to possible emergencies in and around Erdemir. Our team consists of employees working in different units of Erdemir at different echelons and with different titles. We organise regular training and drills to make sure that our team is always ready for possible emergencies. In ERDAK, professional emergency response equipment are kept in special containers in an always well maintained and active state.

We signed a protocol with the local authority of Ereğli to respond to any emergency and participate in research and rescue operation within the municipal borders if tasked.

0 850 211 3000

0 850 211 3000